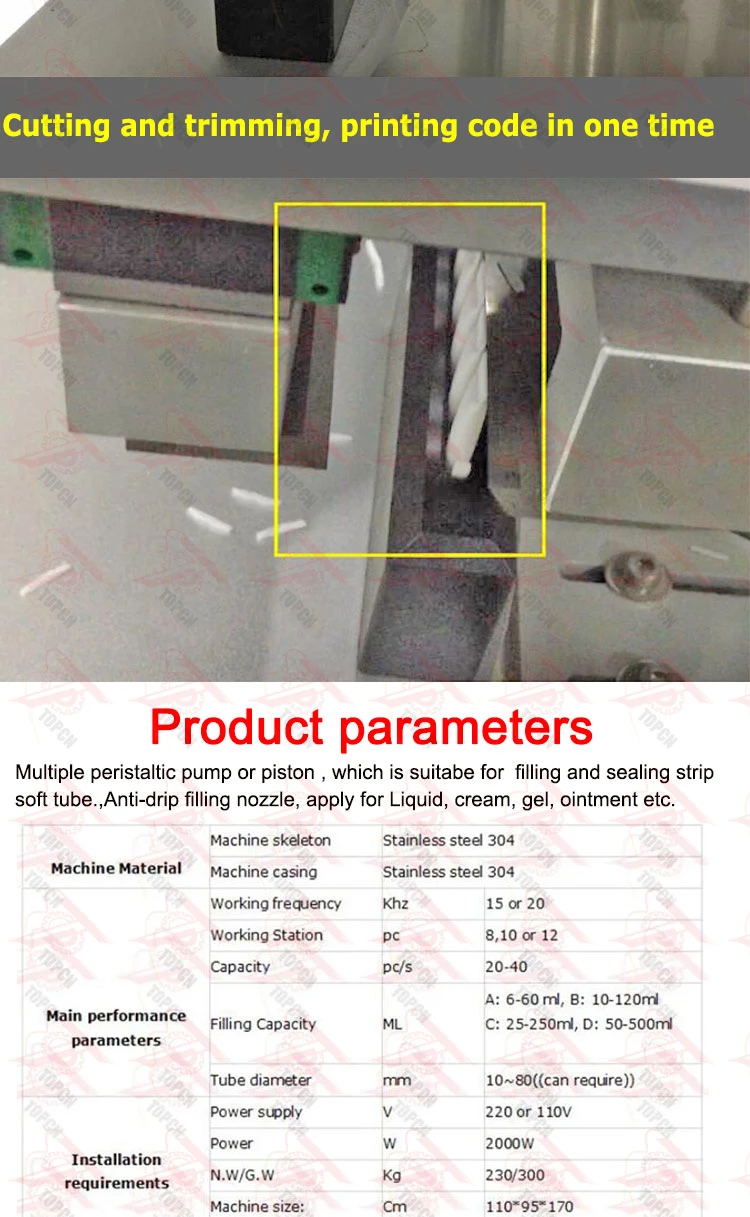

Product Paramenters

The process of cream tube filling machine eliminates the use of glue and allows the thermoplastic parts to

bond to itself. tube filling machine for paste or cream ultrasonic sealing with the proper time setting and pressure is the fastest most reliable method for a variety of tube material sealing.

* Eliminate use of consumable material

* Produce airtight and watertight seams

* Increase production time

tube filling machine cosmetic main features

1. Auto Tube Feeding; Automatic rotary table with 10 tube holders, servo motor control

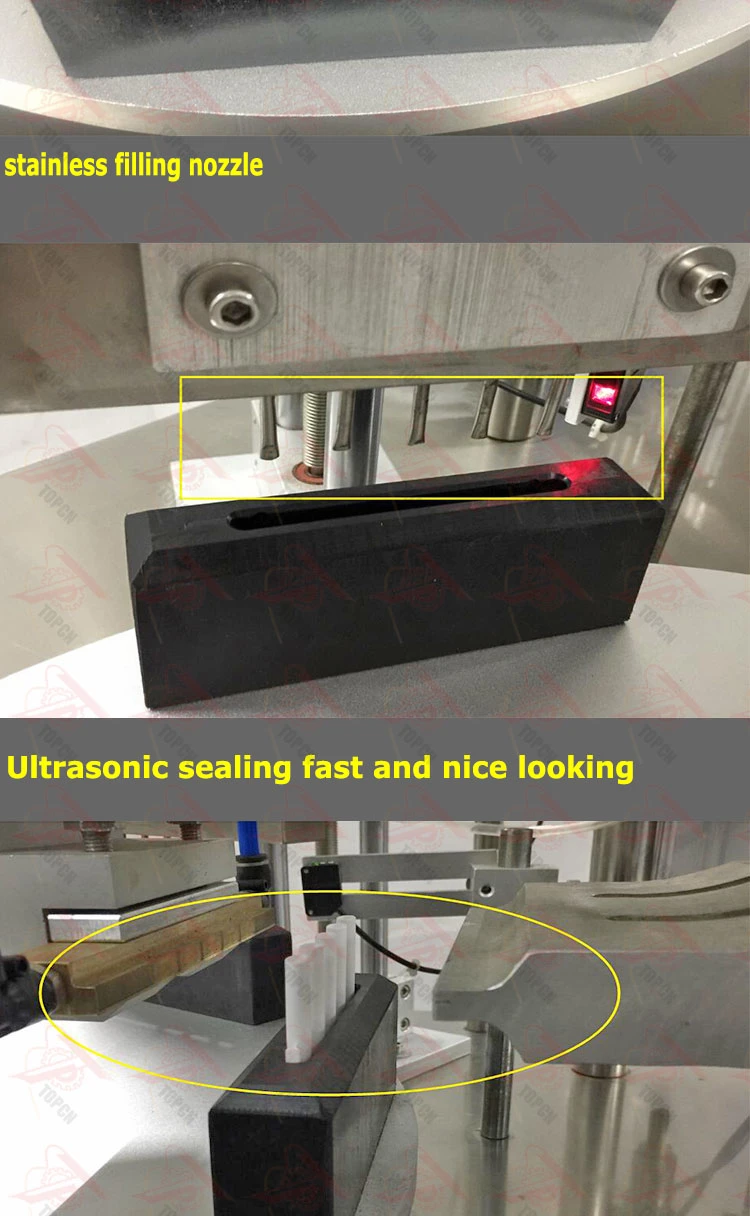

2. Adopt digital ultrasonic circuit, stable output and performance

3. Machine body of stainless steel, meet with GMP requirement

4. PLC/HMI control, simple operation and parameters setting

5. Machine with mark searching function, more precise sealing

6. Main parts adopt imported components, Japan and Taiwan

7. Suitable for plastic tubes, composite tubes, PE tubes.

8. Ultrasonic ampoule tube filling and sealing machine compared with traditional type heat sealing method, the ultrasonic automatic tube filling machine has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, no plastic melting overflow

* Lower power consumption, energy saving

bond to itself. tube filling machine for paste or cream ultrasonic sealing with the proper time setting and pressure is the fastest most reliable method for a variety of tube material sealing.

* Eliminate use of consumable material

* Produce airtight and watertight seams

* Increase production time

tube filling machine cosmetic main features

1. Auto Tube Feeding; Automatic rotary table with 10 tube holders, servo motor control

2. Adopt digital ultrasonic circuit, stable output and performance

3. Machine body of stainless steel, meet with GMP requirement

4. PLC/HMI control, simple operation and parameters setting

5. Machine with mark searching function, more precise sealing

6. Main parts adopt imported components, Japan and Taiwan

7. Suitable for plastic tubes, composite tubes, PE tubes.

8. Ultrasonic ampoule tube filling and sealing machine compared with traditional type heat sealing method, the ultrasonic automatic tube filling machine has the following advantages:

* Fast Sealing, save time

* Sealing is nice looking, no plastic melting overflow

* Lower power consumption, energy saving

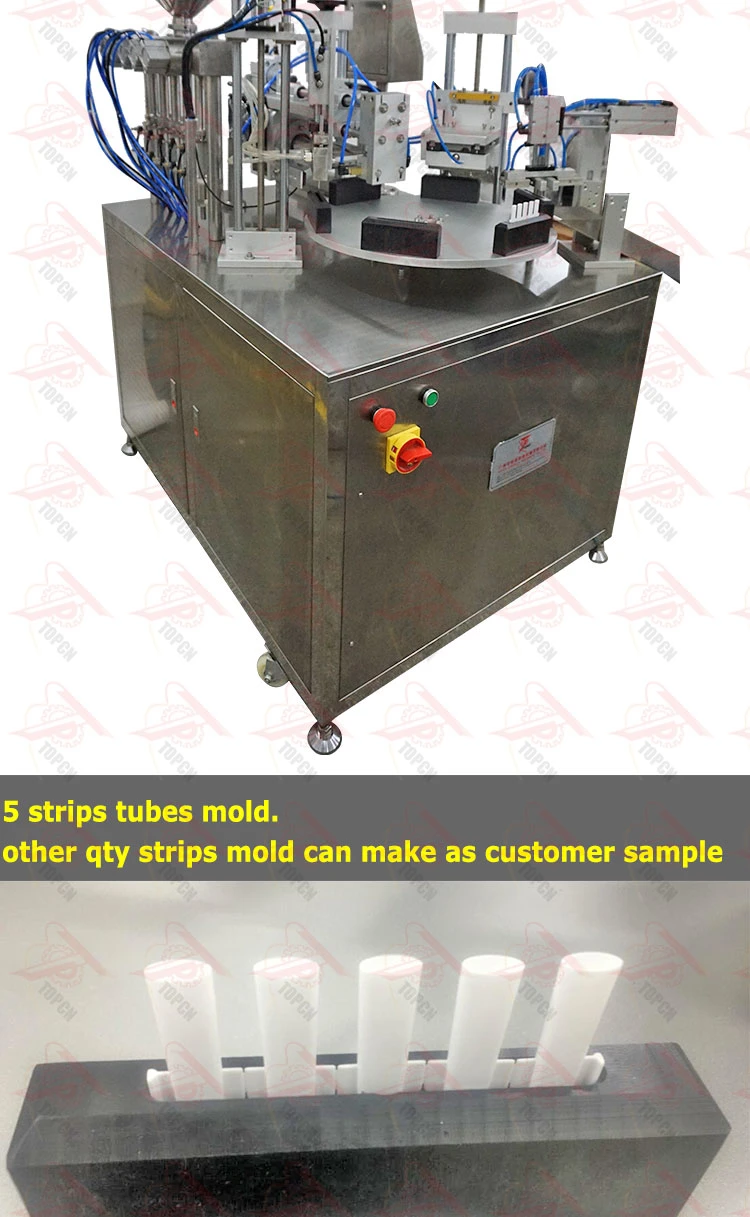

latrasonic automatic 5 7 strips ampoule plastic cosmetic tube filling and sealing machine for paste or cream tube filler sealer | ||||

tube filling machine cosmetic | cream tube filling machine | tube filling machine for paste or cream | ampoule tube filling and sealing machine | tube filler and sealer |

Ultrasonic Power | 2000 W | |||

Frequency | 20 KHz | |||

Power Supply | AC 110/220V, 50/60Hz | |||

Delay Time | 0.01-2.99 S | |||

Weld-time | 0.01-2.99 S | |||

Hold Time | 0.01-2.99 S | |||

Driven Mode | Pneumatic | |||

Stroke | 75 MM | |||

Working Pressure | 0.5-0.7 MPa | |||

Tube Diameter Range | 5-50 MM | |||

Tube Height Range | 10-250 MM 0.35m²/min | |||

Filling Range | A: 5-60 ml B: 10-120 ml C: 25-250 ml D: 50-500 ml | |||

Filling Accuracy | ±1% | |||

Working Station Number | 10 | |||

Hopper Volume | 30 L(Customer-made available) | |||

Capacity | 20-35 tubes/min | |||

Packing Dimension | L*W*H 1683*1550*1750MM | |||

Gross Weight | 680 KGS | |||

HS Code | 8422 303090 | |||

FAQ

Q1: Are you a machine manufacturer or trading company?

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke,how to solve the problem?

A7: Yes, we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke,how to solve the problem?

A8: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides,we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q9: Do you have manual or operation video for us to know more about the machine?

A9: Yes, we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke,how to solve the problem?

A10: Yes, we will send you the manual and operation video after you ask for us.

Q11: If there's some spare parts that broke,how to solve the problem?

A11: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side

A1: We are a reliable machine manufacturer that could gives u best service. And our machine can be customized by client's requirement. Welcome to visit our factory!

Q2: How do you guarantee this machine normally operating?

A2: Every machine is tested by our factory and other client before shipping, We will adjust the machine to optimal effect before delivery. And spare is always available and free for you in warranty year.

Q3: How can I install this machine when it arrives?

A3: We will send the engineers overseas to help client installing, commissioning and training.

Q4: Could I choose the language on touch screen?

A4: It's no problem. You can choose Spanish, French, Italian, Arabic, Korean, etc,.

Q5: What should I do to choose the best machine for us?

A5: 1) Tell me the material you want to fill, we'll choose the suitable type of machine for you to consider.

2) After choose the suitable type of machine, then tell me the filling capacity you need for the machine.

3) At last tell me the inner diameter of your container to help us choose the best diameter of the filling head for you.

Q6: Do you have manual or operation video for us to know more about the machine?

A6: Yes, we will send you the manual and operation video after you ask for us.

Q7: If there's some spare parts that broke,how to solve the problem?

A7: Yes, we will send you the manual and operation video after you ask for us.

Q8: If there's some spare parts that broke,how to solve the problem?

A8: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides,we'll send you the spare parts for free, but the shipping cost should be paid by your side.

Q9: Do you have manual or operation video for us to know more about the machine?

A9: Yes, we will send you the manual and operation video after you ask for us.

Q10: If there's some spare parts that broke,how to solve the problem?

A10: Yes, we will send you the manual and operation video after you ask for us.

Q11: If there's some spare parts that broke,how to solve the problem?

A11: First of all, please take the pic or make a video to show the problem parts.

After the problem is confirm from our sides, we'll send you the spare parts for free, but the shipping cost should be paid by your side